From its tragic sinking in 1912 to current day, the Titanic has retained its capture on audiences worldwide. Whether it’s through famous James Cameron films or recurring expeditions, the stories told have continually captivated audiences and embedded themselves into modern mainstream interest. The wreck now rests nearly two and half miles deep in the North Atlantic, split in two, the bow and stern sections sitting about two thousand feet away from one another. Surrounding the superstructures is a massive expanse of debris, littered with both artifacts and structural pieces from within the ship.

For 2024, the expedition’s goals are to map and image the site like never before, surveying the area with both cameras and lidar, enabling future 3d reconstruction of the site and debris in situ with millions of images. Evan Kovacs, founder of Marine Imaging Technologies and National Park Service’s partner on the SeaArray – the state of the art multi-camera photogrammetry system – will be the Director of Underwater Photography on this expedition. Brett and I will be joining him along with his imaging intern Josie Clapp for the next month while offshore to collect imagery on the site.

Not without having my fill of lobster rolls and clam chowder along the way, I head up to Falmouth, MA — Marine Imaging’s headquarters — to meet Brett, Evan, Josie, and the remainder of the Marine Imaging team. Everyone is full throttle ahead at helping pack, arrange, and prepare for the upcoming expedition. Shortly after saying our initial hellos we all scatter to get as much done in the two days remaining onshore. I head to Providence to meet the Dino Chouest (the ship we’ll call home for the next month) and pick up the camera housings, while Brett and Evan head to Boston to set up servers and storage for the incoming overload of images.

I get into the Providence port just in time to watch the Dino make its way in and throw its line over. As I sit in the car waiting for the gangway to be lowered, I can’t help but be in absolute awe at the scale of all the ships and machinery running around the port. Troy Launay, the expedition co-leader greets me and gives me a thorough rundown of what has been done to the ship in preparation for such an expedition. Having the ship properly outfitted ensures it will be capable of having two ROVs in the water at a time. One of which will be flying with a lidar and magnetometer while the other will be running lanes with a photogrammetry array. As soon as the gangway is lowered Troy disappears onto the ship and arranges for the pelican cases with housing to be unloaded. With the precious cargo in my possession I return to Falmouth, sneaking in just one more lobster roll in on the way before the next month offshore.

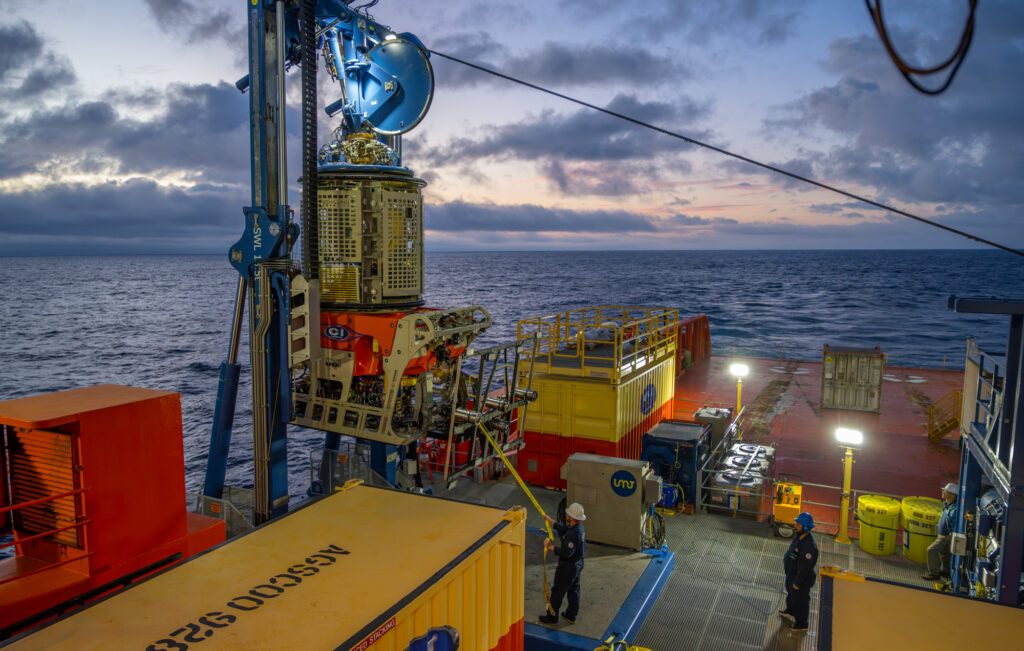

The next morning all hands are on deck preparing and packing every possible spare and necessary component for our trip, if only Marine Imaging’s shop could fit into one magical pelican case. Always better to have extras and not use them rather than be stuck on-site and out of options, with over a four-day transit time and multiple teams pushing to get a massive amount of area covered no one wants to be the cause of any setbacks. As soon as we arrive at the port and meet the Dino set up begins right away, but not without first doing a lap and getting acquainted with our new home, its many decks, and its many many stairs. This is the first time I get to check out the ROVs that will be diving, and they could not be more impressive, a true feat of engineering, and some of the most advanced ones in the world of deep-sea operations. With a lot of setups yet to be done we head to the back deck where we have been given a control van to make our headquarters for the duration of the expedition.

The servers that will hold each subsea image (and its duplicate backup copy) carefully get hoisted onto the ship using one of its many cranes, four petabytes of storage isn’t light. As the raids get set up and switched on the fans kick in and we start getting used to the immense noise and heat that will be generated just a few steps from our desks. Keeping the servers happy is of the utmost importance, the entire expedition relies on them functioning properly and safeguarding each image, and as we soon learn they heat up quickly. Constantly monitoring their internal temperatures and adding A/C units, inventive ducting, and fans all around seems to do the trick in keeping them at an appropriate temperature. Once our storage system is setup, we quickly shift gears towards the cameras that will be acquiring all the data.

Taking an image on the ocean floor over two miles deep is no simple feat, but depth plays a relatively minor part in relation to the challenges of maintaining camera control and communication, all of which is done through fiber optics. The ROV runs fiber from the sub to the surface in its tether, on either end that fiber is split to accomplish many tasks from control to backups for cameras and ROV function alike. With multiple components on the sub needing fiber for control and a limited amount in its tether, cameras make up just one of the strands of glass fiber that will make its way from the ocean floor to our control van. Both at the surface and on the bottom this single strand is split numerous times, each camera runs a fiber into a control bottle that then merges them and delivers a single strand to the control van, which then needs to be reseparated by wavelengths to regain control and communication which each individual camera. Its effectiveness all comes down to the amount of light that can be delivered, and each connection decreases its efficiency. At a certain point from either too many connections or the connections themselves being dirty the amount of noise (loss) is too high and camera communication is lost altogether.

With the entire project relying on these strands of glass fibers you can imagine the nerve-wracking stress that comes with dealing with them, whether it be to disconnect/reconnect them, route cables, or secure them to the sub. Exposure to dealing with them constantly helps dilute the nerves, but even better is watching a professional like Evan deciding on a whim to redo nearly all the connections at any given moment to get rid of as much light loss as possible.

With fiber connected and cleaned everywhere it can the little time remaining is spent learning the software we’ll be using to control camera parameters and record data to the servers. One of the many screens that will be sitting in front of will show us live feed from the three cameras on the photogrammetry array so we are able to adjust parameters like aperture, shutter, and focus on the fly depending on proximity, speed, and light availability. We head to bed after a blur of days spent packing, unpacking, and getting acquainted with our new home. No one will be sleeping for long as we have just left port and in a few hours get to drop the ROVs off the continental shelf for their first shakedown with the cameras in some deeper water. After that it will be a four-day transit before we reach the Titanic wreck site, where I’ll be writing again!